Tidal wave - FloWave, Edinburgh

Capable of making 28m-high waves, the University of Edinburgh's FloWave is the world’s largest circular wave and tidal tank.

The 25m-wide, 5m-deep pool was built to test wave and tidal energy machines (which convert the ocean’s energy into electricity), as well as for basic research on how waves are made at sea.

Using 168 computer-controlled paddles, visible here around the edge, FloWave can produce waves and tidal currents in any direction.

Recently, Edinburgh researchers teamed up with Oxford University academics to better understand how 25m-plus ‘freak waves’ can form when waves travelling in different directions cross paths. These giant waves are thought to have sunk many a ship over the centuries.

The plume of water in this photo, however, is a ‘party trick’, and wouldn’t occur naturally. Like a stone’s throw in reverse, ripples made at the edge of the tank travel towards the centre, where they converge and shoot two tonnes of water straight up in the air.

Read more:

- How to stop a hurricane

- Monster movers: 6 massive machines for shifting rockets, turbines and even ancient buildings

Earthquakes - E-Defense facility, Japan

The ‘shake table’ at the E-Defense facility (‘E’ stands for ‘Earth’) near Kobe, Japan, is the largest in the world.

The 20m by 15m platform hides an array of 24 pneumatic pistons, which are controlled by engineers to shake full-scale buildings in three directions, at earthquake-level intensities.

When Texas A&M University engineer Dr Maria Koliou visited in February 2019, she got to wander around these fully furnished, wood-framed houses and then watched as her Japanese colleagues ran their shake programmes – one of which simulated the 6.9 magnitude Kobe earthquake that destroyed 150,000 buildings in 1995.

“It was pretty impressive,” says Koliou. “I hadn’t seen a full-scale test before.”

The right-hand building was even grounded in soil with pipes running through it, to get closer to real-life conditions.

The Japanese scientists surveyed the structural damage caused to the houses, with the aim of learning how building companies can better protect people’s homes during earthquakes.

Wildfires - Wildfire simulator, South Carolina

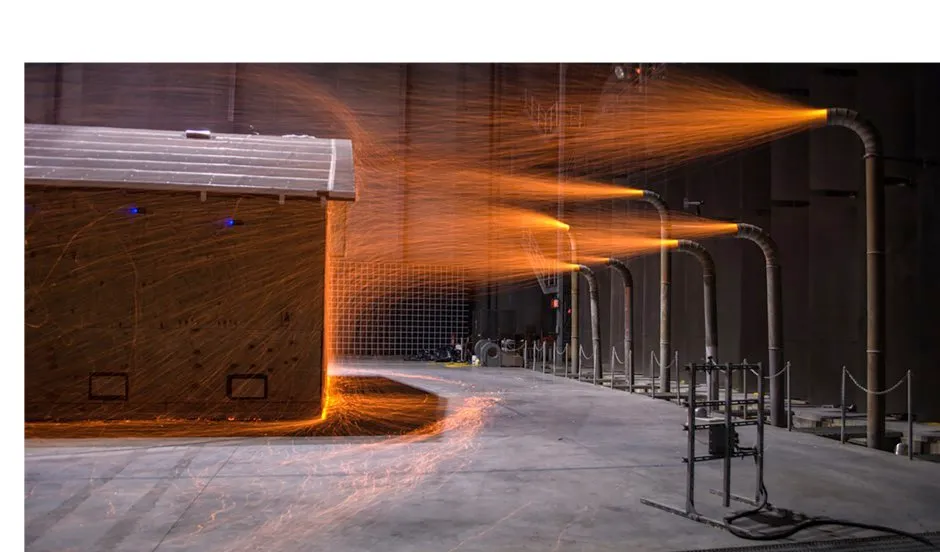

Wildfire spreads like... well, wildfire, in this specially designed wind tunnel in Chester County, South Carolina.

This is part of a six-storey research facility belonging to the Insurance Institute for Business and Home Safety (IBHS).

The tunnel is used to simulate what happens when burning embers are driven by wind to produce the ‘ember storms’ often seen in wildfires, which can be devastating to nearby buildings.

On the right of the picture, embers – made in chambers filled with mulch and wood – are blown across the test space from metal ducts. The building sits on a rotating platform so that the embers can be blown from different directions.

Researchers examine how the embers get into buildings through vents, and look at how decking and debris can help wildfires to spread.

In this picture, plants below the front windows are acting as kindling, while the wooden step outside the front door is also adding fuel to the flames.

Tornadoes - Debris Impact Facility, Texas

You can’t shoot a bullet through a brick wall, but fire a piece of wood at it hard enough and you might have more luck.

Here, the strip of wood shatters, but it isn’t quite moving fast enough to break through the bricks. However, at 160km/h, it rips right through, as researchers at the Debris Impact Facility at Texas Tech University have demonstrated by firing a piece of wood from their pneumatic cannon.

Even though a bullet shot from a gun moves faster, a strip of wood is heavier, so the impact is greater. This explains why debris thrown at high speed by a tornado can cause so much damage.

The researchers use their cannon to simulate the impacts of flying debris in tornadoes travelling at up to 400km/h, testing storm shelters, safe rooms, doors and windows to their limits.

Extreme temperatures - Scania test facility, Sweden

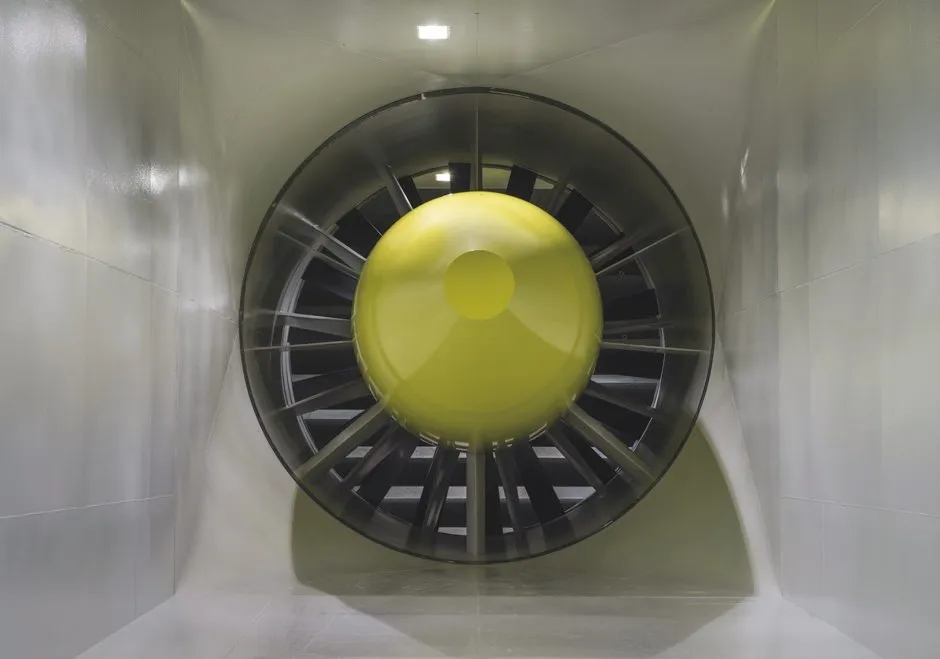

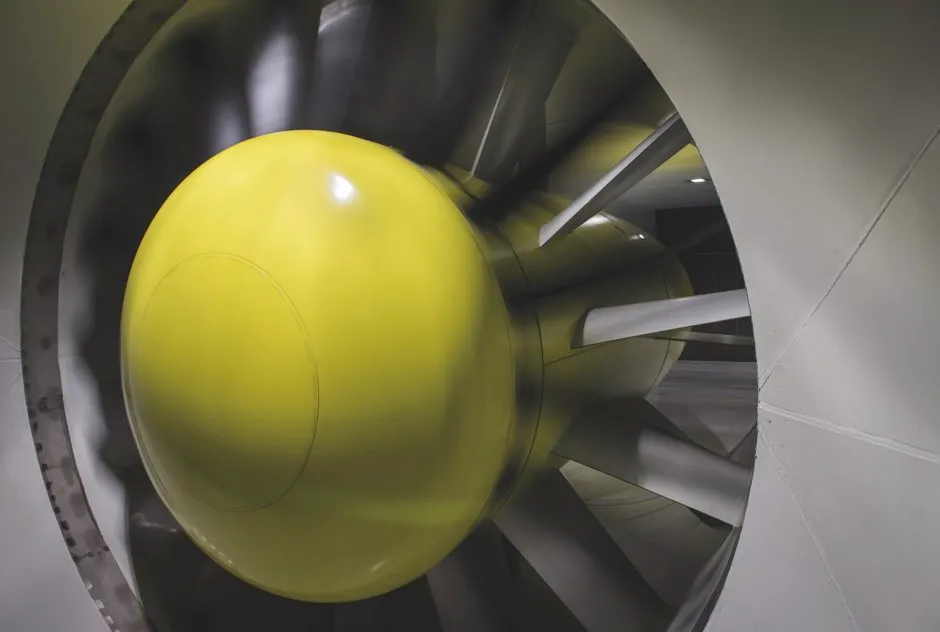

At this sophisticated climate facility in Södertälje, Sweden, you can control the weather.

Developed by truck manufacturer Scania at a cost of £33m, it took three years to build and is intended for testing heavy vehicles in the harshest weather conditions.

The snowdrifts in this picture were produced by snow cannons like those used at ski resorts, while a single 3.75m-high fan provides the wind for snow storms.

On another day, conditions could be more akin to a desert heatwave, thanks to a temperature control system that goes as low as -35°C and up to 50°C.

The humidity can range between 5 and 95 per cent, and even the droplet size of simulated rain is adjustable.

Rollers under the parked vehicles allow the researchers to mimic speeds of up to 100km/h as they study variables such as driver visibility, windscreen wiper function, and the reaction of different components.

Scania hopes that its facility will help improve fuel efficiency in demanding conditions, cutting down vehicles’ emissions.

Volcanoes - University at Buffalo, New York

How do you cook up volcanic lava in the lab? A team at the University at Buffalo in New York has the recipe down: take 45 litres of basaltic rock, put it in a furnace, bake for four hours until it reaches 1,316°C, then pour it into an insulated steel box.

In this photo, volcanologist Dr Ingo Sonder stirs the lava.

His experiments examine “the basic physics of what happens when water gets trapped inside molten rock”.

This could help scientists learn more about explosions like the one that triggered the Icelandic ash cloud event in 2010, when meltwater from a glacier flowed into the erupting Eyjafjallajökull volcano and threw ash 9km into the air, leading to the cancellation of nearly all European flights for five days.

By injecting water into DIY lava, Sonder’s team has discovered that spontaneous explosions are more likely to occur when water meets lava at a depth below the surface exceeding 30cm. At shallower depths, the water can escape as steam before it causes an explosion

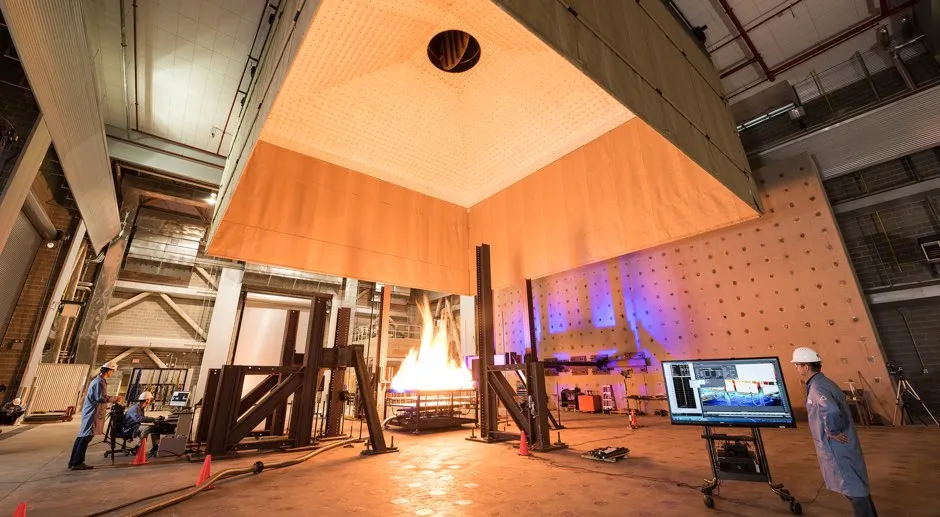

Fire -The National Fire Research Laboratory,Maryland

Although they aren't natural disasters like the wildfires that ravage homes and buildings from the outside, fires that start from the inside can be equally as devastating.

To understand how we can build better buildings and safer structures, the National Fire Research Laboratory has built an enormous facility with 3,000m² of experimental space that can create controlled fires up to 20 megawatts in size, four times greater than a car fully ablaze.

With the ability to gather real-time data about the structural integrity of a new material during a fire, scientists are able to test whether they are suitable for construction, and can replicate blazes in buildings and rooms up to nine storeys tall.

As if you needed proof as to how important these studies are, you should see the difference between what happened when they ignited a watered christmas tree and a dry one

See more pictures

- This article was first published onBBC Science Focusin April 2019, with additional reporting by Alexander McNamara forsciencefocus.com –subscribe here

Follow Science Focus onTwitter,Facebook,InstagramandFlipboard