In the Batman movies, the Dark Knight’s cape pulls off a neat trick. Most of the time it billows behind him while he crumples nameless henchmen, but when Batman needs to make a quick escape, he can leap off a building and stiffen his cape so that it works like a glider that carries him into the night. One moment the cape is fluid, then the next it’s rigid. It’s a smart bit of engineering that engineers at Caltech and JPL have now replicated in the real world.

This material, inspired by chainmail, can go from a foldable, fluid-like state into a specific solid shape with the application of pressure. The researchers behind it hope this tech could potentially be used as a smart fabric for exoskeletons, or even as an adaptive cast to be applied to a broken limb, to keep your bones where they need to be.

The physics behind the technology will be familiar to anyone’s who’s bought vacuum-packed coffee, explains Chiara Daraio, a professor of mechanical engineering and applied physics at Caltech. “Think about coffee in a vacuum-sealed bag. When still packed, it is solid, via a process we call ‘jamming’. But as soon as you open the package, the coffee grounds are no longer jammed against each other and you can pour them as though they were a fluid,” she says.

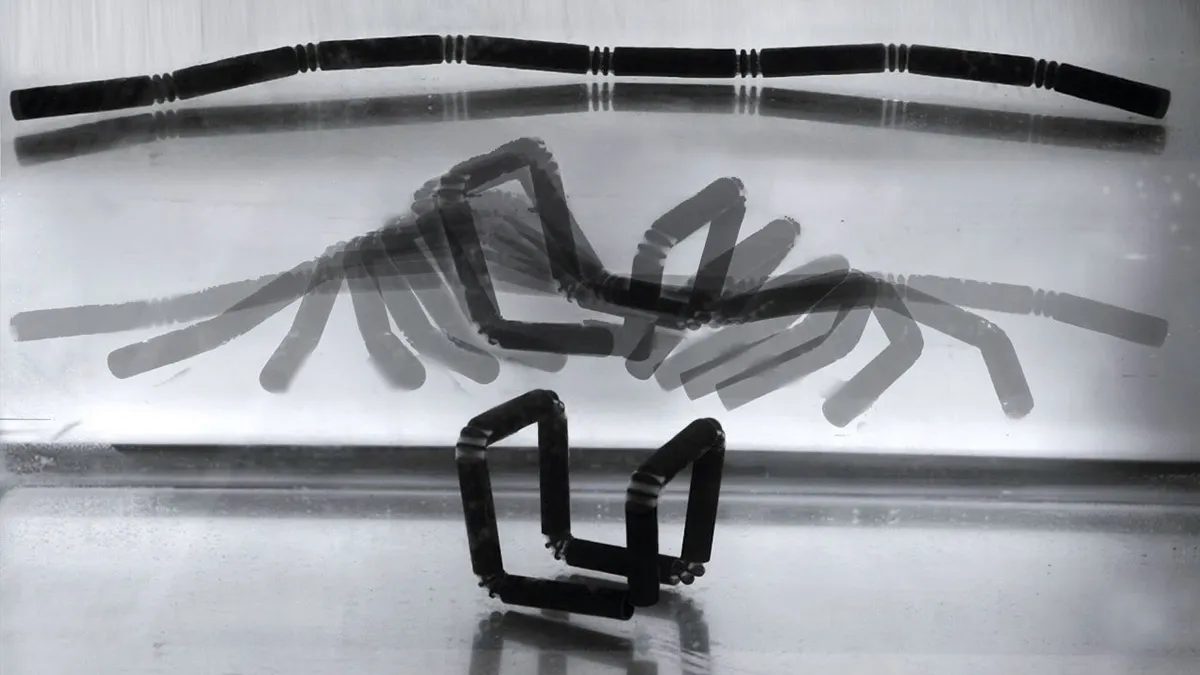

To discover the chainmail that would be the most flexible at rest and the stiffest under pressure, the team 3D-printed different configurations of linked particles and tested each in a computer simulation.

The researchers chose an octagonal shape for the links, even though that doesn't produce the stiffest fabric possible. "If we are looking to provide the largest possible stiffening effect in a fabric, or in designing a material that can show the highest resistance to bending, then the octahedron is not the optimal shape," said Daraio. "Surprisingly, ancient chain mails (with circular or square linked elements) are much better at that!

"However, circular rings and squares based chainmail are also much heavier (because they pack more densely). So if our goal is to find the optimal material for wearables, we may need to define optimality parameters that are different and more specific.

"For example, find the particle shape that gets us to the largest stiffening AND the lighter weight. In general, the more average contacts we can get between two particles, the higher the stiffening effect will be."

In one demonstration, the fabric was able to support a load more than 50 times its own weight.

In parallel research, Daraio and her team are investigating strips of polymers that shrink when heated. These strips could be woven into this new type of chainmail to create solid objects – like bridges – that fold down flat when not needed. The two materials working together could also, she suggests, create robots that can morph into different shapes to solve different problems.

Read more about futuristic materials:

- Engineers create ‘living materials’ inspired by kombucha tea

- Mantis shrimp ‘clubs’ inspire a new generation of super tough materials

- Environmentally friendly 'living concrete' capable of self-healing

3 more programmable materials

Climate-Active textiles

Researchers in MIT’s Self-Assembly Lab have created ‘climate-active’ textiles. Seemingly built for the UK’s indecisive weather, the materials respond to temperature changes by contracting in the cold to close up gaps in the fabric, then relaxing in the heat to breathe.

4D Printing

4D printing is what happens when you add materials to 3D printing that change shape in the presence of water or heat. It means you could, for example, create pipes that expand when it’s cold to avoid ice creating a crack.

Adjustable wings

Carbon fibre that changes shape when exposed to heat or water creates a strong material that can respond to the environment. One street-legal race car has a rear wing that opens or closes depending on the rain, creating more downforce when it’s wet to improve traction to the rear tyres.