Scientists have developed what they call living concrete by using sand, gel and bacteria.

Researchers said this building material has structural load-bearing function, is capable of self-healing and is more environmentally friendly than concrete – which is the second most-consumed material on Earth after water.

The team from the University of Colorado Boulder believe their work paves the way for future building structures that could “heal their own cracks, suck up dangerous toxins from the air or even glow on command”.

Wil Srubar, who heads the Living Materials Laboratory at the University of Colorado Boulder and is one of the study authors, said: “We already use biological materials in our buildings, like wood, but those materials are no longer alive.

“We’re asking: Why can’t we keep them alive and have that biology do something beneficial, too?”

Read more about building materials:

- Smart material made from squid teeth a potential plastic alternative

- How is curved glass made?

- Terminator-style stretchable metal created in lab

For their experiments, the team worked with cyanobacteria – green microbes that live in the water and can manufacture their own food.

While these bacteria are quite small and usually unicellular, they often grow in colonies large enough to see.

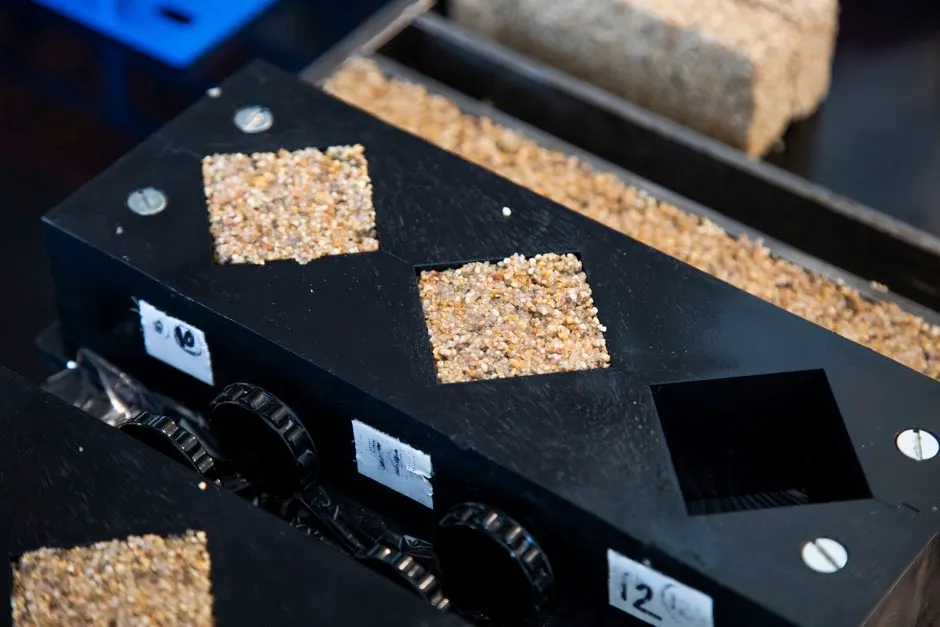

The team created a scaffold using sand and hydrogel for the bacteria to grow in.

The hydrogel contains moisture and nutrients that allow the bacteria to reproduce and mineralise, a process similar to the formation of seashells in the ocean.

These microbes absorb carbon dioxide from the air and make calcium carbonate, the main ingredient in cement.

Reader Q&A: Could we 3D print a house?

Asked by: Megan Jackson, Age 9, Abergavenny

It’s already happening! Scaled-up 3D printers that use concrete instead of plastic filament have been used to build wall sections for several years.

And in 2016, Huashang Tengda (a Chinese construction firm) 3D printed an entire two-storey house. The steel reinforcing bars were still installed by hand, but then a concrete extruding robot printed the walls around them in just 45 days.

Read more:

Mr Srubar said: “It’s a lot like making rice crispy treats where you toughen the marshmallow by adding little bits of hard particles.”

The team said their hydrogel-sand brick is also capable of reproducing, demonstrating self-healing capabilities.

Researchers found on splitting a lab-grown brick in half that it grew into two complete bricks with the help of some extra sand, hydrogel and nutrients.

Mr Srubar said: “It really demonstrates the capability of exponential material manufacturing.”

The research is still in its early stages and the team said more work needs to be done to address some of the drawbacks.

The team’s cyanobacteria, for example, need humid conditions to survive so Mr Srubar and his team are working to genetically engineer microbes that are more resistant to drying out so they remain alive and functional.

The research is published in the journal Matter.