Flick through any collection of popular science magazines from the last 50 years and the chances are that you will encounter a feature about nuclear fusion. Nuclear fusion is the process of joining lightweight atoms together to release energy; it is the reason the Sun and the rest of the stars shine, and recreating that process on Earth promises an abundant form of low-carbon energy.

As you look through the archival material, keep an eye open for when the pundits think fusion might arrive. It’s an old joke that whatever the decade of the publication, fusion has always been “about 20 years away”. Yet despite five decades of effort, no fusion plant can yet produce more energy than it takes to start the reaction.

But don’t let that bare fact make you think that fusion is as far away as ever. There has been a sea change recently that has shrunk the 20-year horizon to a mere decade away. For a start, there has been an increase in our understanding of the science of fusion. Second, there has been an undoubted set of technological breakthroughs. But it is the third reason that may be the deciding factor: a change in mindset.

“The most important single thing that’s changed in the world of fusion, in my opinion, over the last decade, is the very clear realisation that we need fusion,” says Tim Bestwick. He is the chief technology officer and director of strategy, communications and business development at the UK Atomic Energy Association (UKAEA).

He explains that the two principal factors in this realisation are climate change and energy security. In regard to climate change, fusion offers an abundant source of low-carbon energy that can be used in combination with renewable energy sources such as solar and wind power. This has been accepted for years now, and while energy security has also been talked about for a long time, the sharp need for it has only just recently come into focus, particularly with Russia’s invasion of Ukraine causing many countries to rethink how they buy in energy and fuel from foreign powers. This all loads the dice in favour of fusion.

The UK’s fusion effort is headquartered at the Culham Centre for Fusion Energy in Oxfordshire. This is the home of a long-running experimental fusion reactor called JET, the Joint European Torus. JET is a tokamak, a five-metre-wide doughnut-shaped vessel. The name derives from a Russian word meaning ‘toroidal chamber with magnetic field’.

Since starting operations in 1983, it has made major advances in understanding both the science of nuclear fusion and the engineering required to make it happen. And for inspiration, the researchers need only look up into the sky…

Creating the Sun on Earth

The Sun is the nearest natural fusion reactor to Earth. Deep below its glowing surface, the temperature soars to 15 million degrees Celsius, and the pressure and density is similarly gigantic. Under these conditions, fusion naturally occurs. It starts with hydrogen and proceeds through a series of interactions that force the hydrogen nuclei together. First the reactions build isotopes of hydrogen and helium, and then ordinary helium itself.

For an artificial fusion reactor, it is impossible to recreate the kinds of pressures and densities found inside the Sun. Inside JET, for example, the gas density rarely rises above that of the ordinary air outside, and so to compensate, the temperature must be boosted to more than 100 million degrees Celsius.

At such temperatures, the gas becomes electrically charged. This state of matter is known as a plasma, and because of its electrical charge, it can be controlled by magnetic fields. The magnetic field is essential because no material can contain a gas at more than 100 million degrees Celsius. The magnetic field accelerates and controls the flow of the plasma within the reactor, allowing the particles to fuse and release energy.

“JET has been an extraordinary machine. It has hugely outlived its expected life. I think its significance is around the fact that it is a deuterium-tritium machine,” says Bestwick.Deuterium and tritium (DT) are isotopes of hydrogen. After a number of experiments at JET over the years, it’s clear that deuterium and tritium will be the fuels that make fusion viable. So now that the science is sorted, the next step is for the engineers to actually build a reactor capable of generating more energy than it needs to run. This is where ITER comes in.

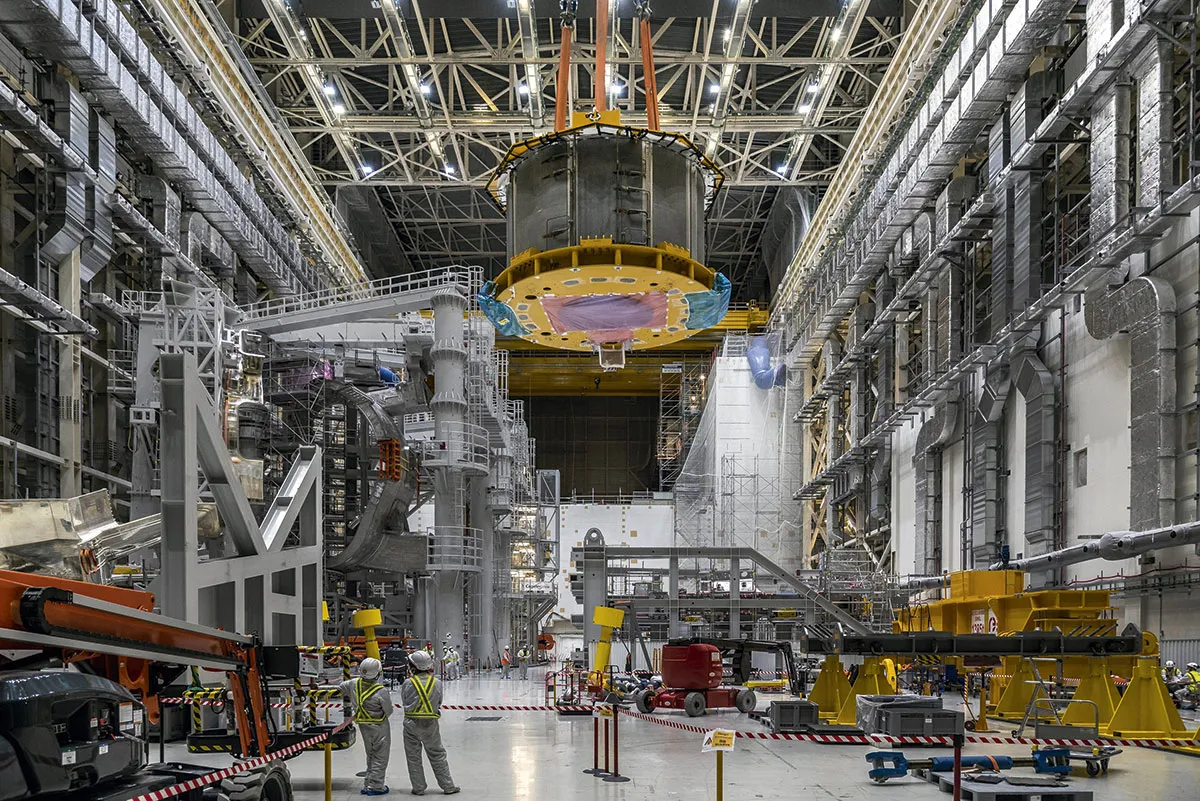

ITER is a tokamak twice the diameter of JET. It is being built in southern France by a consortium of 35 countries, including the UK. The tokamak itself is scheduled to be completed in 2022, but then it must be encased in its surrounding machinery. Operation is expected to begin in 2025, followed by a decade of gradually ramping up the reactor to its full capacity. Eventually, ITER is expected to be able to return 10 times the energy required to start the process.

Beyond ITER, UKAEA is also designing a reactor called STEP (Spherical Tokamak for Energy Production) that will be the world’s first prototype nuclear fusion energy plant. The site for its construction will be chosen by the end of this year. Construction is slated to begin in the 2030s, with commissioning several years later. And they are not alone.

Sharing knowledge

The diffusion of knowledge about what it takes to spark fusion, combined with the march of technological progress, mean that building a commercial fusion power plant is now largely an engineering challenge, rather than a leap into the scientific research and development. As a result, the last few years have seen a profusion of private companies interested in developing their own approaches to fusion.

“Twenty years ago, fusion was the preserve of governments. Now there are more than 25 private fusion companies around the world and they’re attracting huge amounts of investment,” says Valerie Jamieson, who manages the newly inaugurated Fusion Cluster at Culham.

Aiming for its official launch later this year, the Fusion Cluster is attracting start-up companies interested in building or contributing to fusion reactors. They will be housed next to JET’s facilities, allowing expertise and opportunities to build up in one place. It’s a tried and tested formula.

“The best-known technology cluster is Silicon Valley,” says Jamieson, “Having all your customers and collaborators nearby just oils the wheels and makes everything run more smoothly.”

Another UK science cluster exists at the Harwell Science and Innovation Campus, also in Oxfordshire. It started around a decade ago with a handful of companies and now boasts more than 100 space organisations. Of course, when it comes to private space companies, the most obvious success story is Elon Musk’s SpaceX, which now routinely ferries astronauts to and from the International Space Station. This is the sort of success that the cluster hopes to emulate.

The successes have already begun for two of the more established companies in the cluster. Tokamak Energy recently achieved the necessary plasma temperature for fusion in their one-metre-wide reactor, and First Light Fusion achieved fusion for the first time using a different approach from tokamaks.

And it is not just reactor companies that the cluster wants to attract. It also wants companies that can provide essential services for the reactors. Two of those essential services are robotics and artificial intelligence.

Robotics inside the fusion reactor

Just across the campus from JET is the UKAEA’s Remote Applications in Challenging Environments (RACE). Inside their hangar-like work area, a giant robotic arm is being tested. Once the reactors are up and running, humans will not be able to enter the reactors to perform maintenance. This is because deuterium-tritium fusion produces its energy in the form of neutrons, which create high levels of short-lived radiation. So robots will perform the tasks that humans cannot.

This already happens at JET, where a 12-metre-long robotic arm with two ‘hands’ is remotely operated by a team of technicians. Called MASCOT, it can snake its way into the tokamak and replace wall tiles, tighten screws or remove worn components. While the technicians are highly skilled at controlling the arm – they play Jenga with it as part of their training – it is still a slow process. Therefore, similar but more sophisticated devices for ITER will be needed.

In the high-radiation environment of the reactor, electronics can be swiftly degraded. This is why the robotic arm being tested at RACE is covered in dots, the positions of which are precisely measured by special cameras. When the arm is stressed by heavy loads or movement, the pattern of dots distorts slightly. This is measured by the cameras and can be translated in to a kind of ‘pain map’ of the arm, showing how it is performing.

If the system works, the vulnerable electronic sensors inside the arm can be stripped out, making the system cheaper to manufacture. As an added benefit, knowing when you are approaching the design capabilities of your machine will allow it to be used to its utmost efficiency.

“The motive for using robotics always comes down to safety, productivity or both,” says Robert Buckingham, the director of RACE. And the applications of the robotics being developed here spin out far beyond fusion. They could be adapted for any hazardous environment: underwater or in space for example. And while the actual robot for these environments may look very different, what is ‘under the hood’ is remarkably similar.

“You’ve got sensors that are looking at what’s around you, and you’ve got a computer to make decisions, and motors to move the robot. There’s an awful lot of commonality,” says Buckingham.

Artificial intelligence to control the reaction

Hand-in-hand with making these robots as responsive and autonomous as possible is artificial intelligence. Fusion cluster company Luffy AI is the brainchild of data scientists Matthew Carr and Alex Meakins. The pair met while working on Culham’s other fusion reactor, MAST (Mega Amp Spherical Tokamak).

They realised that controlling the conditions in a fusion reactor needed AI, yet current systems had hit a wall. While AI is great in the digital world, at recognising faces, for example, it was not making such advances when used to control pieces of equipment such as robots or reactors.

After analysing the problem, Carr and Meakins decided that the basic problem was that traditional artificial intelligence systems stop learning once they have been trained. If they encounter an unknown situation, they flounder. To solve this problem, they have coded the machine equivalent of neuroplasticity, the process by which we adapt our behaviour to the environment we find ourselves in.

They are currently training drones how to fly, so that if a rotor is lost, the machine will invisibly adjust and the user will notice little to no difference in the handling, although clearly performance will be affected. In the future, one can imagine fusion reactor control programmes that invisibly adjust to the rapidly altering conditions inside the plasma, to maintain the highest fusion efficiency possible. It’s heady stuff. A bold, inspiring future is being created at Culham, and it is promised to be closer than we ever thought.

If things continue to go as planned, then in 50 years’ time when someone comes across this article, they will realise it was written at a turning point when fusion stopped being “20 years away” and instead was just around the corner.

Case studies

First Light Fusion

There are a number of approaches to nuclear fusion. Beyond the swirling plasmas of the tokamaks, another approach is called ‘inertial fusion’. In this method, a fuel pellet is compressed to temperatures and densities that allow fusion to take place.

At the National Ignition Facility (NIF) in the US, the compression is achieved by a bank of 192 extraordinarily powerful lasers. At First Light Fusion, a private company that is part of the Culham fusion cluster, it is achieved by shooting a target containing the fuel with a projectile fired from a hyper-velocity gun.

The projectile is accelerated to 6.5 kilometres per second, but when it hits the target, the top secret design focuses and amplifies the impact to make the fuel implode at over 70 kilometres per second. This triggers fusion and releases a pulse of energy.

First Light founder Nicholas Hawker heard about fusion while doing his A-Levels in the early 2000s, but it was not until his PhD that he took up the mantle to study how to advance inertial fusion, which back then was a completely new approach. “Being off the edge of the map and finding new ways of doing things is what really appealed to me,” says Hawker.

Now that the technology has been shown to work, First Light is designing a demonstrator reactor to be built in the second half of the 2020s. First Light is also working towards completing a pilot power plant in the 2030s, in line with other fusion start-ups and government-run initiatives.

Tokamak Energy

The stronger the magnetic field of a tokamak, the more control it can exert over the plasma, and so the smaller the reactor can be. Tokamak Energy, in common with other labs around the world, has developed strong devices called high-temperature superconducting (HTS) magnets. These produce magnetic fields almost a million times stronger than the Earth’s natural field.

Tokamak Energy recently achieved a plasma temperature of 100 million degrees Celsius in a small reactor built entirely with private funds. In total, the reactor is about four metres high and three metres across, but its volume is 30 times smaller than any other that has achieved that temperature. Now, the researchers plan to build a new reactor using the HTS magnets they have developed. It should be a game changer.

“You can get high performance in smaller devices. You can learn faster, the cost of devices goes down, you’re closer to an ultimate commercial goal,” says David Kingham, the executive vice chairman and former chief executive officer.

He points out that while experimental plants such as ITER are vital for investigating the science of fusion, it is the smaller, cheaper reactors that will turn the technique into viable power stations.

“Our 10-year goal is for a pilot plant using the technology that would scale into a commercial power plant. Then within five years of that, so within 15 years from now, start to deploy power plants globally at scale,” says Kingham.

- This article first appeared inissue 379ofBBC Science Focus Magazine–find out how to subscribe here

Read more about nuclear fusion: